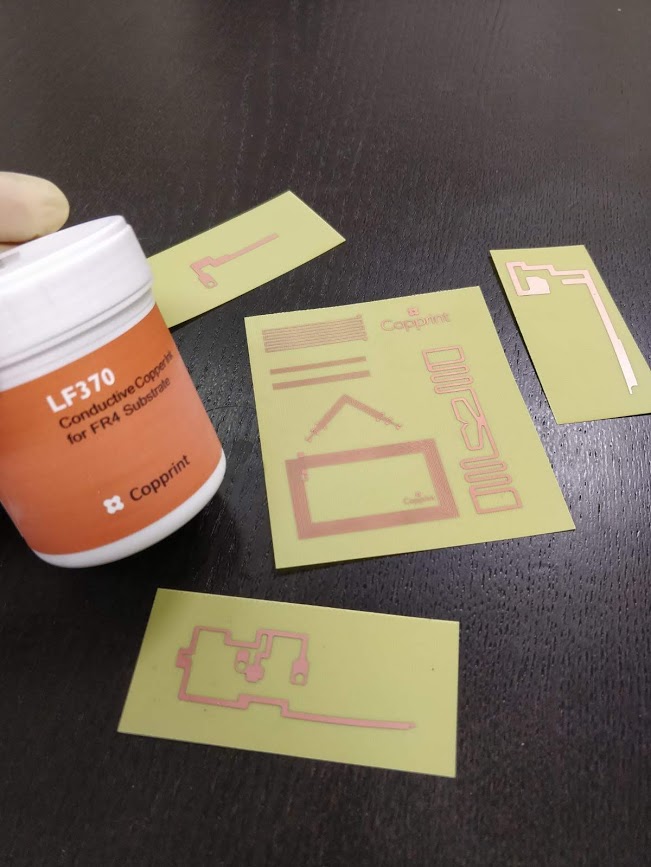

TYPICAL PROPERTIES OF COPPRINT NANO COPPER PASTE (UNCURED)

Particle Size, μm D50 < 1.0, D90 < 7.0

Solid Content, after 30 minutes @150ºC, 90%

Density, 4 g/ml

Viscosity @ r.t., DVEHA Brookfield spindle 14, mPa∙s (cps) 12000-17000

Coverage area @5μm dry film thickness, 11.4 m²/kg

Shelf Life, @<-10°C, 180 days

Pot life @ 25°C, Hours 72

Drying and Sintering:

Drying cycle

120sec @90ºC (Hot air, Reflow oven)

Sintering cycle

R2R option: 12 sec @170°C (laminator)

S2S option: 120 sec @140-160°C (Hot Pressing)

Relaxation cycle

PET: 120 sec @ 140C (Hot air, Reflow oven)

PC: 120 sec @ 110C (Hot air, Reflow oven)

Conditions (time and temperature) may vary based on customers’ experience and their application requirements, as well as customer drying equipment, oven loading and actual oven temperatures.

TYPICAL PROPERTIES OF CURED MATERIAL Physical

Properties

Adhesion: (tape test 3M Scotch 234) pass

Cross cut test ISO 2409-2007 3-4 b

Electrical Properties: Sheet resistivity

S2S (Hot press), ohm/□/25 µm <0.006

R2R (Contactless Laminator), ohm/□/25 µm <0.009

DIRECTIONS FOR NANO COPPER INK USE

Copprint LF-360 is supplied as a single-component formulation ready for use.

SCREEN PROPERTIES

Emulsion, Solvent resistant emulsion: 10 to 40 μm

Squeegee Shore Hardness: 70 to 90 Shore

Screen Type: Polyester screen, mesh 90 to 300

EQUIPMENT MAINTENANCE & CLEAN-UP

The equipment can be cleaned with Dowanol DB followed by water and repeated if necessary.

STORAGE

Store sealed container under -10°C in a dry location.

(Long storage above -10°C can adversely affect product properties.)

Paste removed from containers may be contaminated during use. Do not return Paste to the original container. Copprint is not responsible for paste which has been contaminated or stored under faulty conditions

Safety information

For safe handling of Copprint Nano Ink consult the

Safety Data Sheet (SDS).

Technical Data Sheet

For technical data please see the

Technical Data Sheet (TDS)